Dive Boat Anchor Construction Richard Jacquot Here's a small report on my new anchor I built for my dive boat. When I went to the Cooper River in September, one thing I didn't like was the anchor. I was using a 20 lb. Danforth anchor, it didn't work very well and had a hard time grabbing the river bottom, especially when the current was ripping. I decided to get another anchor before my next trip out. I looked online at several different ones, most of them were pretty pricey. When I looked at the stainless steel, the prices were sky high! I decided to visit my local scrap yard and see what I could find.

After a couple of visits I was able to pick up several pieces of stainless rod, square stock, etc. I cut angles on the hex pieces, cut the rods to length and designed my new anchor.

I took the pieces to my welder friend that does all my boat welding. He used stainless electric rod and we spent about an hour welding the pieces together. Once finished I spent another three hours polishing the steel.

Bear Cat checking out the finished product.

The finished product...well, almost finished. I plan to add another piece of stainless 1/4" thick x 5" x 12" plate at the bottom that wraps around to help grab the river bottom. Then a little more polishing. I'll post another pic here when I am done. October, 2010

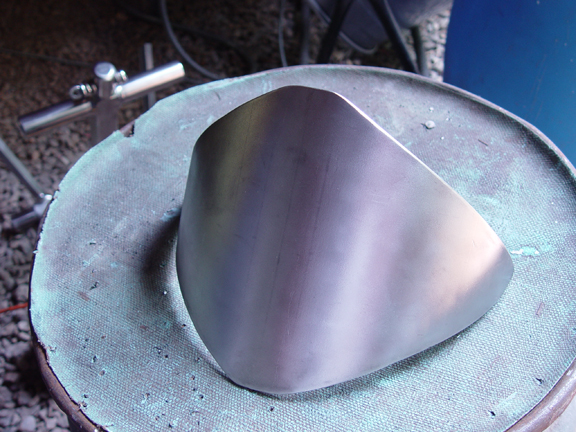

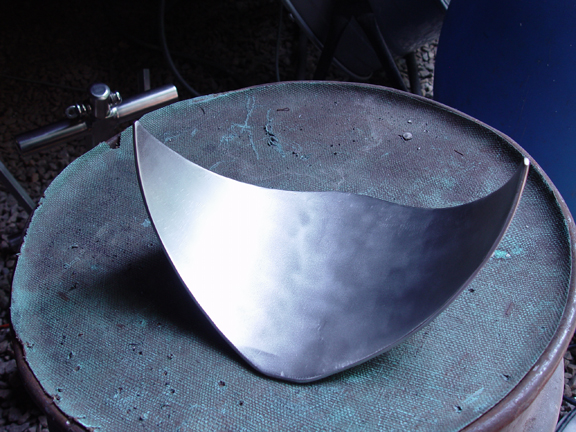

Well its June, 2011 and I decided it was time to finish the anchor to use on our dive trips this month. I went back to the scrap yard and found this stainless piece of 3/16" pipe cut in half. I drew my pattern and took it down to the shop to cut.

I had forgotten what a pain in the a** it is to cut stainless steel. The last time I cut any, I was using a plasma cutter and it was still hard to get a smooth cut. I had to use my old school acetylene gas torch to cut the piece. It was slow going but I finally got it done.

Next was a couple of hours of grinding and polishing.

The idea for this piece was to act as a backdrop to catch the river bottom gravel as the spikes dig in. I opted to bolt the piece on in case it ever gets bent, although it would take a lot to bend 3/16" stainless! Overall this was a cheap project. I have $50 invested in the steel. The most expensive part of the anchor is the $25 shackle on top, I had to order that from California. I decided to name the anchor the "Bottom Feeder" as I hope it will dig in and eat the river bottom when it hits.

"Bottom Feeder" 50 pound stainless steel anchor for dive boat, Sadeyn Sirenian |